PEB (Pre Engineered Buildings)

Pre-engineered buildings (PEBs) are a modern and efficient construction method that involves designing and fabricating the building structure in a factory-controlled environment and then assembling it on-site.

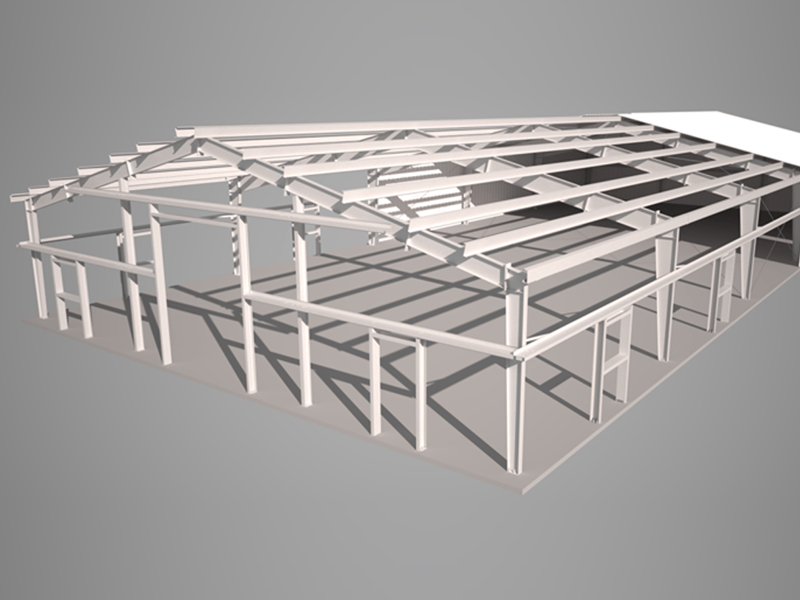

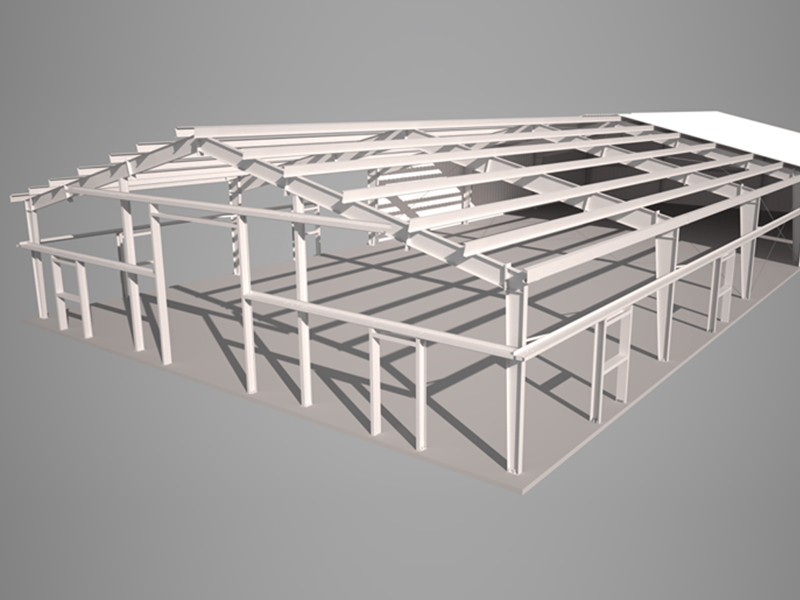

PEBs are designed using advanced computer-aided design (CAD) software, where every component of the building, including columns, beams, rafters, and connections, is pre-engineered to precise specifications. This design phase ensures optimal use of materials and structural integrity.

Components of the building, such as steel frames, roof and wall panels, doors, and windows, are manufactured off-site in a factory. These components are fabricated to exact dimensions and quality standards, ensuring consistency and reducing on-site construction time.

On-site assembly of a PEB involves erecting the pre-fabricated components using bolted connections. This assembly process is typically faster compared to traditional construction methods because it eliminates the need for extensive on-site welding and cutting.